- info@vetropan.com.tr

- +90 534 455 31 22

- Saray Mah. Keresteciler Bul. 230/7. Sk. No:5, 06980 Ankara

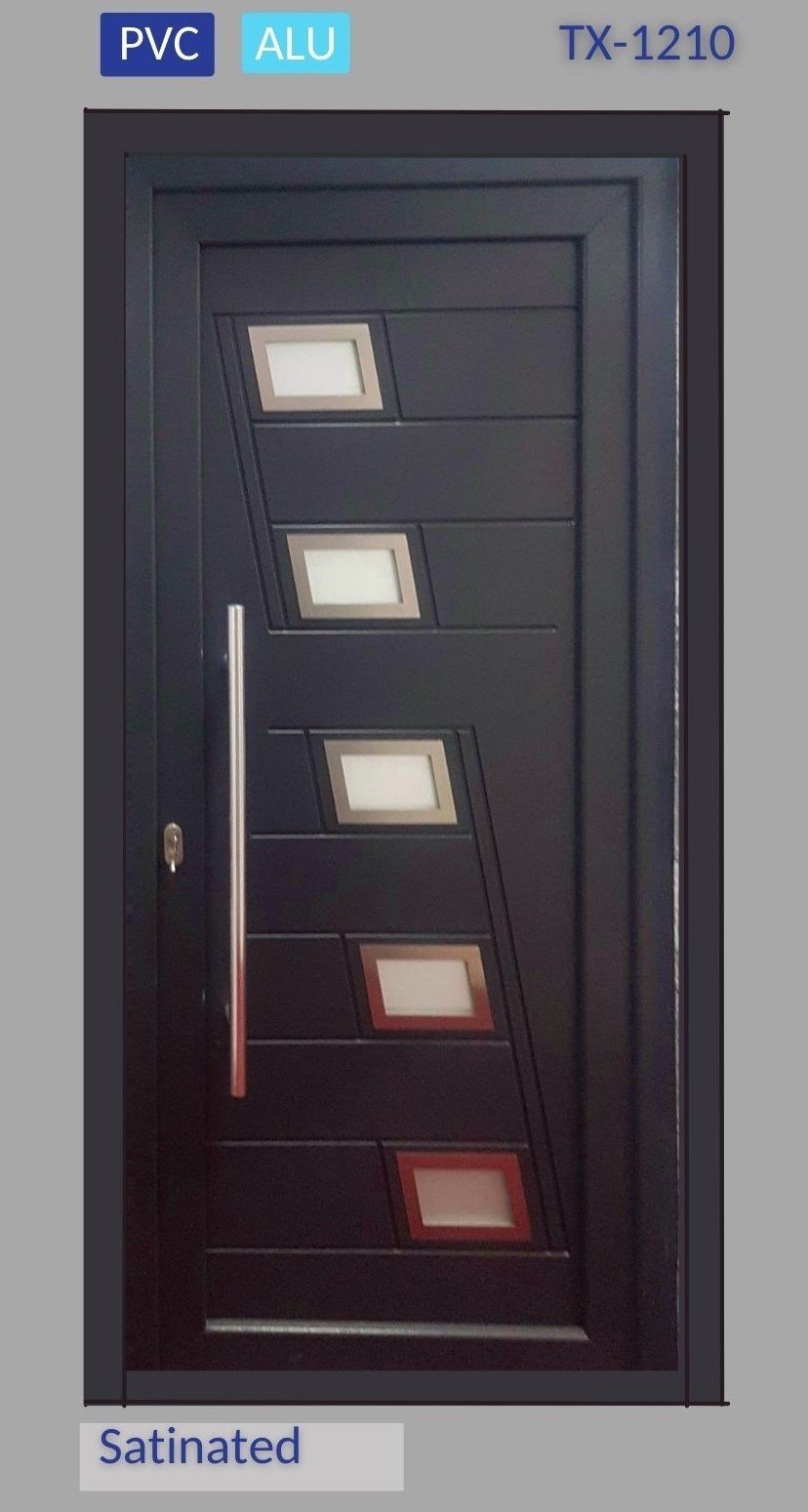

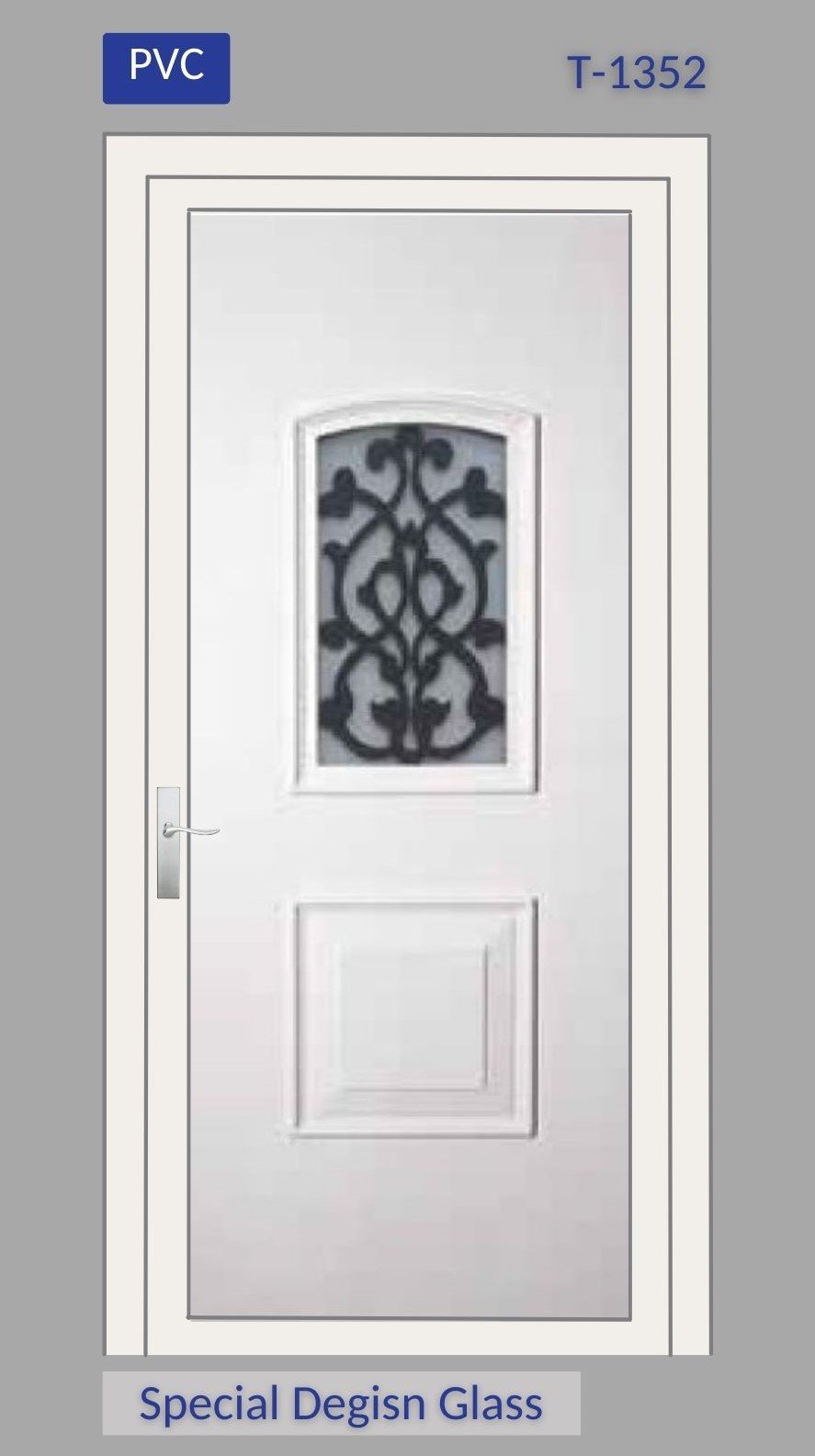

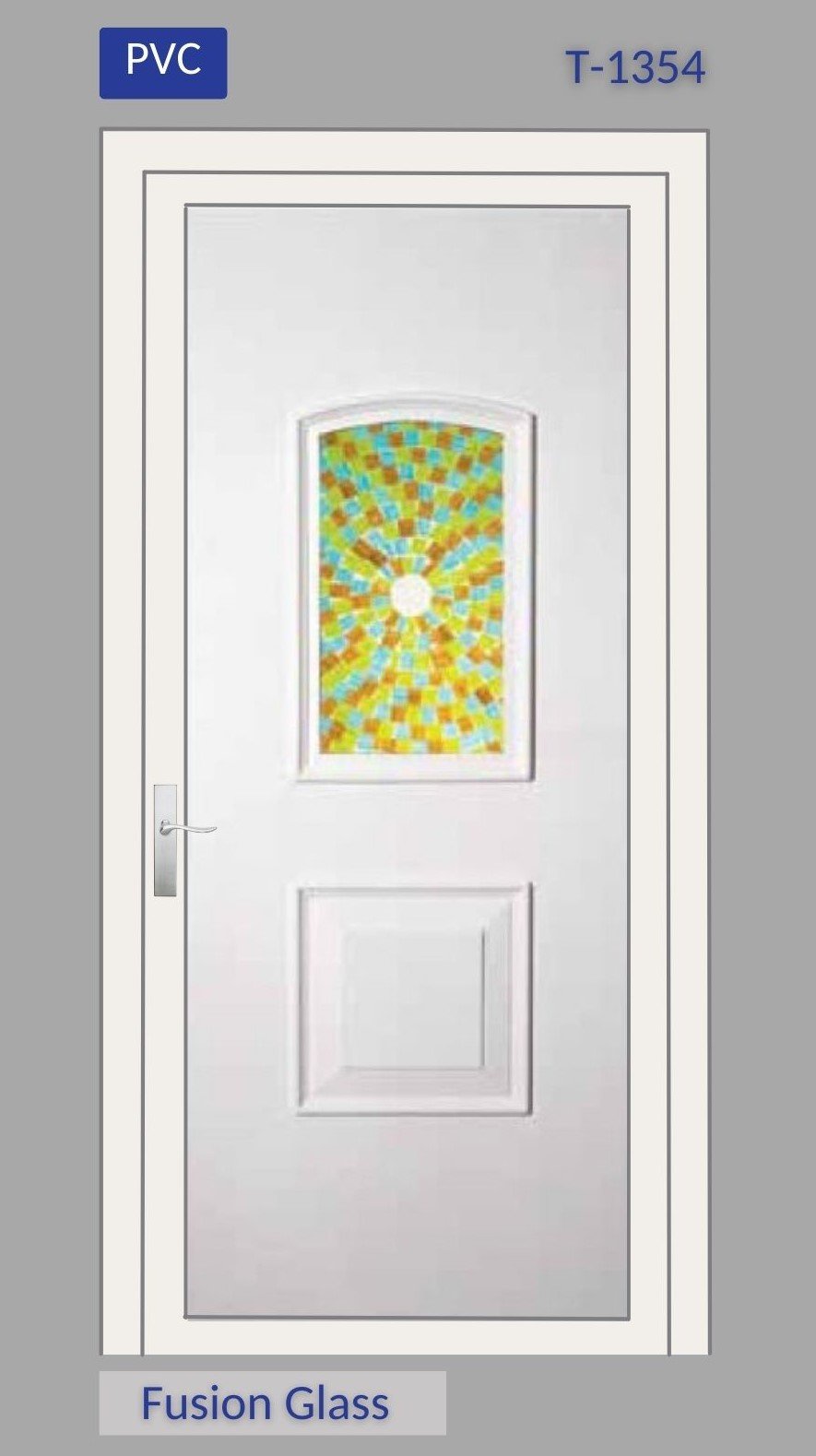

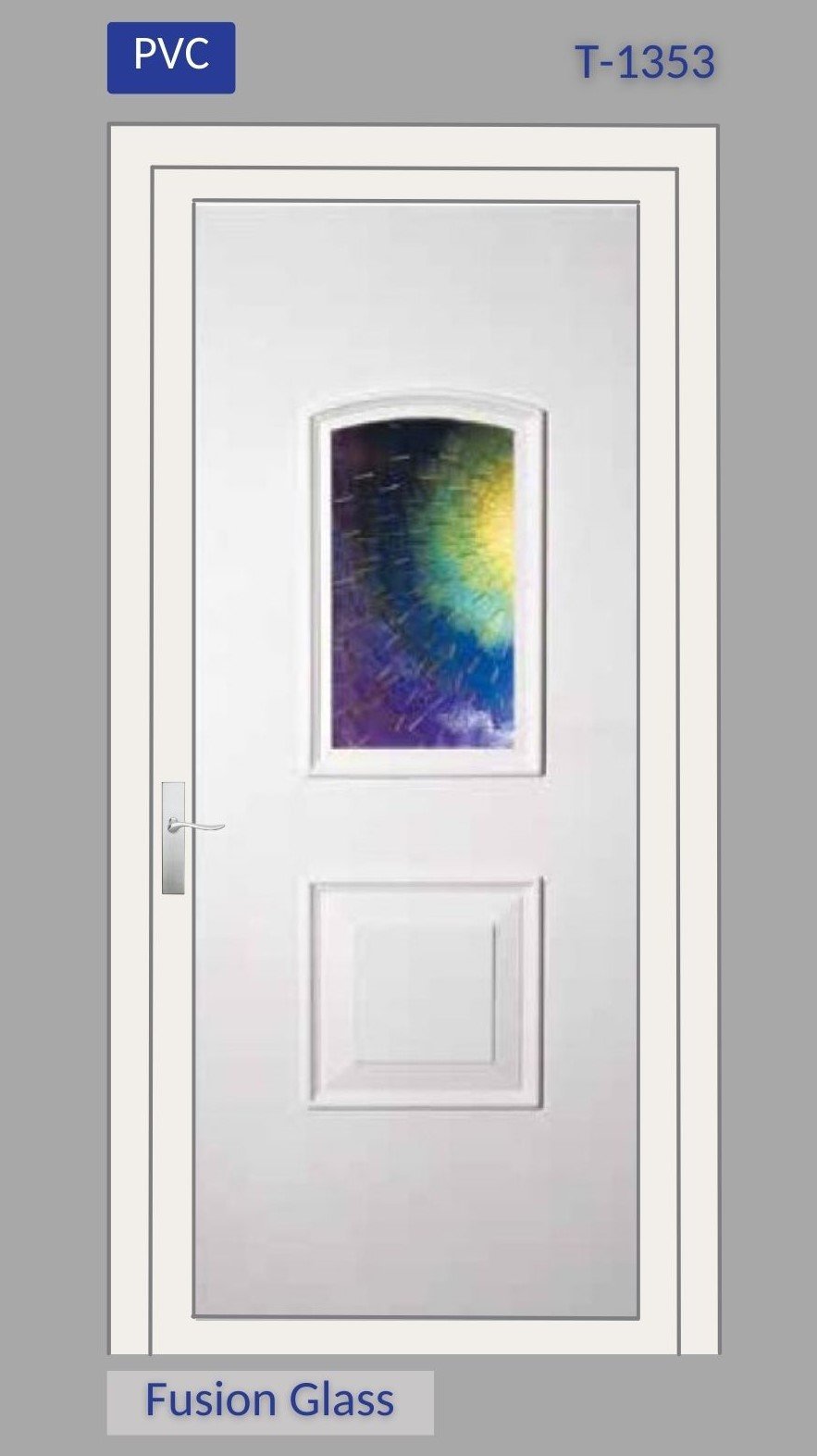

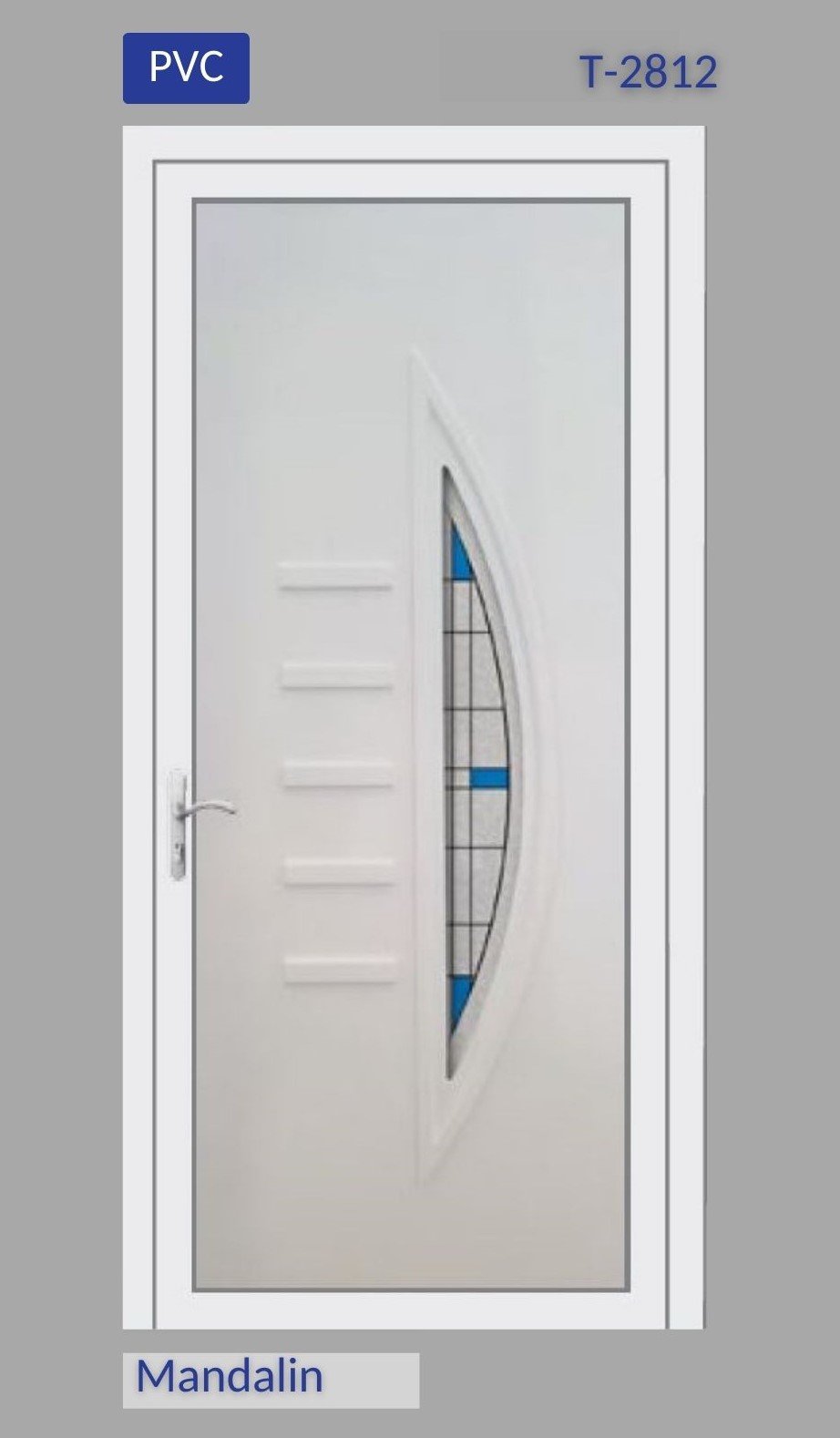

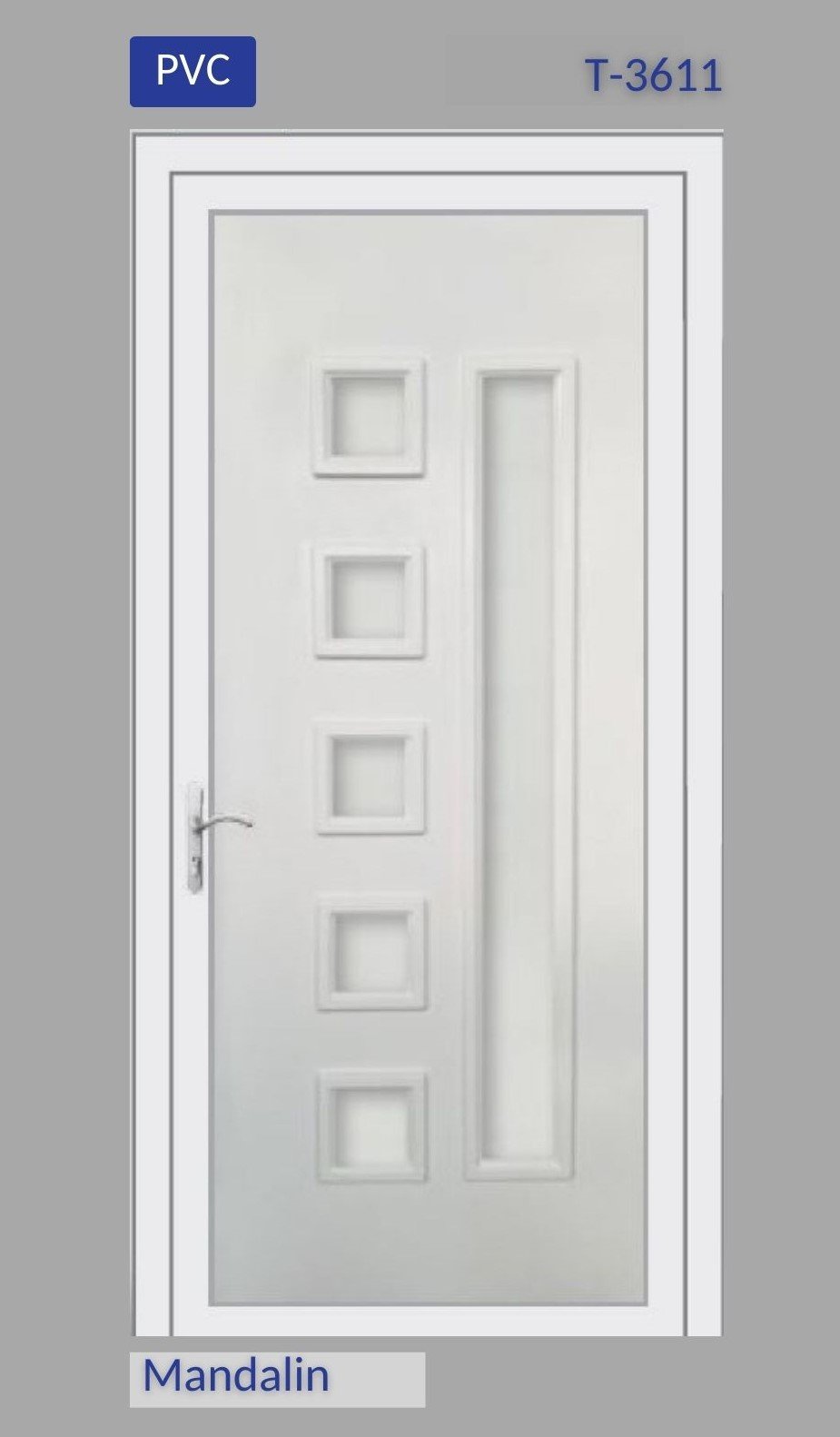

VACUUM FORMED DOOR PANELS

- Vetropan

- VACUUM FORMED DOOR PANELS

MON-FRI 8:30-18:00

+90 534 455 31 22

Product Details

- PVC Sheet: 1,3mm | Surface: Matt | Color Shade: RAL 9016 of medium range

- Laminates: 1,3mm | Surface: Glossy | Lamination Options: Anthrazit Gray, Golden Oak, Mahagony of LG Film

According to project specifications different Sheet thickness’, lamination options and material origin can be available.

At Vetropan, we harness the innovative power of Vacuum Forming technology to create grooved and textured PVC door panels that set new standards in design and functionality. Our Vacuum Forming machine is expertly engineered to mold PVC into high-quality door panels with distinctive textures and intricate grooves that add depth and character to any installation.

This technology allows us to offer a wide range of customizable options, ensuring that each panel perfectly aligns with our clients’ aesthetic and functional needs. Whether you are looking to enhance a residential home with elegant door features or seeking to elevate a commercial space with robust, eye-catching designs, our Vacuum Forming capabilities provide the flexibility and quality you require.

Our process involves heating a sheet of PVC until it becomes pliable, then using a high-powered vacuum to draw it down onto a mold. This method ensures precision in replication and consistency in quality across all pieces, making it ideal for both small custom orders and large-scale productions.

Opt for Vetropan’s Vacuum Forming solutions and benefit from door panels that are not only aesthetically appealing but also durable and maintenance-friendly. Let us help you transform ordinary spaces into extraordinary places with panels that are as functional as they are beautiful.